in Cooling systems Show

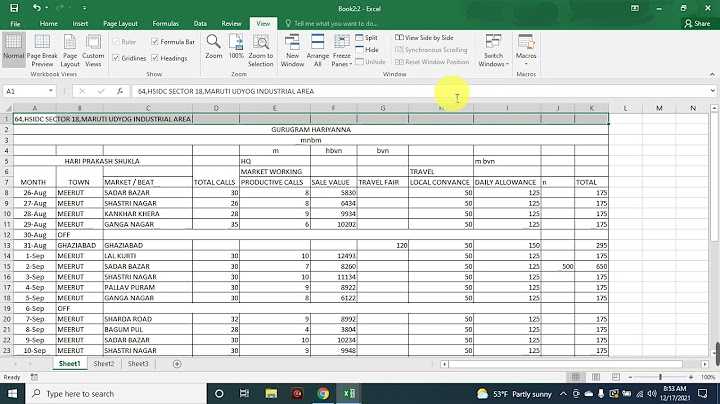

In a fully sealed cooling system , the cap on top of the radiator is not usually opened for topping up the system.  Coolant in a sealed system does not evaporate to the atmosphere, and should never need topping up. Instead, a pressure cap is fitted to the system, and a tube leads from the top of the radiator to a glass, plastic or metal tank or container. Coolant which has expanded as the system warms up passes down the tube into this tank, and is drawn back into the radiator when it has cooled. The system is supposed to be maintenance-free, and is drained only when a hose or the coolant is due for replacement. When draining and refilling the system, if the coolant is to be reused, place clean containers beneath the drain points. Note that the coolant is poisonous. Do not use containers which will be used in or near the kitchen. If you do not want to use the coolant again, do not pour it down a drain — ask your local council how to dispose of it. If you intend to reuse the coolant, have a little extra to hand for replacement, as a little spillage is inevitable. Most manufacturers recommend a 60 to 40 per cent water and antifreeze mixture. Some specify a 50-50 mix. Use antifreeze made to BS (British Standard) 3152, or as specified by the car manufacturer. The standard number, if it applies, is printed on the container. Checking and maintaining the system Make sure the expansion tank cap is clean and sound if you should have to top up. A glass or plastic expansion tank allows you to check the level at a glance. Make sure it is topped up with antifreeze mixture to its maximum level mark. Check the rim and seal on the pressure cap for dirt and deterioration every time that you open it. If the cap has a pressure release valve , never get it wet; replace it if it does become wet or dirty. Examine the condition of the hoses where they are held by clamps or hose clips. Reinforce them with fabric-based tape under the clamps or clips if they are wearing - or, better still, replace them. Check all the clips for tightness, but do not overtighten them and so distort the hose. Tighten all the hose clips and close all the bleed screws. With the engine running and hot, keep topping up the radiator as the air bubbles are dispersed. Trapped air tends to collect at the highest point of the system. Where there are no bleed valves, slacken the return hose of the heater unit - the bottom hose - and allow the air to escape. As soon as there is a steady stream of bubble-free coolant, tighten the hose. Antifreeze, or a combination of water and antifreeze, will stain and discolour paintwork if allowed to dry on it. Use plastic sheeting or absorbent rags to protect wings and other exposed parts of the paintwork. If coolant is spilled onto paintwork, rise it off immediately with clean water. Draining and refilling coolant When refilling, raise up the car on axle stands so that the top of the radiator is the highest point of the system. To empty the system, let the engine cool, take the cap off the expansion tank, put the heater control inside the car on 'hot', and open the drain tap or remove the bottom hose. Open the bleed screws on the hoses and connections. They are usually thumbscrews and can be opened with the fingers. Those on the water pump or other metal fittings may need a small spanner to open them. When refilling, raise the front of the car on axle stands to make the top of the radiator the highest point in the system. Check all the hose clips for tightness and close all the drain plugs, except the bleed screw at the top of the heater hose. Make sure the heater control inside the car is set to 'hot'.  After a few days, beed air from the heater-hose bleed screw. Pour the coolant mixture into the expansion tank until it reaches 1 in. (25 mm) above the top level line. Replace the cap. Remove the radiator cap and fill the main system with coolant through the radiator opening until it will take no more and there is a trickle of coolant from the heater bleed screw. Close the screw. Run the engine until it reaches its normal temperature, when the top hose becomes hot as the thermostat opens. If you have a bleed screw on the water pump , undo it a turn. Close it as soon as a steady, bubble-free stream of coolant comes out. Take care — the coolant is hot and there are moving drive belts near by.  Top up the expansion tank if necessary when all air is out of the system. Top up the radiator. Open and close the bleed screws on the various hoses and connections in turn, ending with the heater-system screw. Close each of them as soon as there is a good flow of air-free coolant. Lower the car. After a few days, with the engine hot and running, set the heater to the 'hot' position and carefully open the heater-pipe bleed screw, or the one at the highest point in the system.

The flow of air into the car can be blocked by leaves or road debris in the supply tubes or in th...

Always use the right kind of antifreeze for your car and keep it at the correct strength, other...

Core plugs are also known as expansion plugs, welch plugs and sealing discs - a point to remember...

A leak in the water-cooling system can be hard to trace - especially if it is internal, say in th...

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website. Hot water heating system expansion tank / compression tank troubleshooting guide:We provide a heating system expansion tank Troubleshooting & Repair Guide. This article series provides a heating system expansion tank (compression tank) troubleshooting & repair guide. We also provide an ARTICLE INDEX for this topic, or you can try the page top or bottom SEARCH BOX as a quick way to find information you need. Signs of Trouble with a Heating Boiler Expansion Tank

The behavior, maintenance, and sources of leaks or trouble are not identical with these two different types of compression / expansion tanks on boilers. A modern internal bladder type expansion tank like this Amtrol Extrol tank (photo at left) is generally trouble free, and it's unusual for these tanks to fail. The Ex-Trol® is properly referred to as a pressurized diaphragm-type expansion tank. [Click to enlarge any image] Both older non-bladder type expansion tanks and even modern (and much smaller) internal bladder expansion tanks can get in trouble. But on occasion the internal bladder in one of these tanks could rupture or develop a leak. If that happens, because the tank is not field-repairable, the "fix" is to install a new expansion tank. But far more often, it is older non-bladder type expansion tanks on boilers, like the one below) that become waterlogged. What Happens if an Expansion Tank Becomes Waterlogged?When the expansion tank is no longer able to absorb this initial pressure increase, it is possible that the heating system's internal pressure would exceed 30 psi - the typical point at which a heating boiler pressure/temperature relief valve will open to spill excess pressure. If the relief valve is forced open in this manner the heating system will first lose water each time a heating cycle starts by heating up the boiler. Then the heating system will take in makeup water (through the automatic water feed valve) each time the system cools down. The result would be recurrent loss and then inflow of water through the boiler, increasing the risk of system corrosion as well as wasting water and possibly causing other damage or operating problems. Watch out: spillage at the pressure temperature relief valve is potentially dangerous: eventually minerals in the water can clog a leaky relief valve, causing it to stop leaking - which might look ok but this means that the relief valve has become clogged - the boiler is operating without this critical safety device and an explosion could occur.  Shown above, an older style ceiling mounted atmospheric expansion tank on a hydronic heating boiler in Two Harbors, MN. The drain valve shown at the left end of this expansion tank is a special valve that makes it easier for replacement air to enter the tank when the tank's water is being drained - a standard procedure during annual heating boiler maintenance. We describe that procedure separeately at EXPANSION TANK DRAIN & AIR RE-CHARGE . [Click to enlarge any image] Trouble signs that could be traced to a water-logged boiler expansion tank include:

Also see HOT WATER PRESSURE EXPANSION RATE How to Diagnose an Internal Bladder-Type Boiler Expansion Tank Needs an Increased Air Charge or Needs ReplacementNewer type heating system expansion tanks that use an internal bladder keep their water and air separated. These tanks should not need frequent service but might need a small additional air charge every few years, as we explained at WATERLOGGED EXPANSION TANK. But there are at least three possible conditions for which to check an internal bladder type expansion tank for trouble.

Additional Diagnostic Tests for a Waterlogged Heating Boiler Expansion Tank Our illustration at left shows the typical location of a traditional conventional, non-bladder-type heating boiler expansion tank, and is adapted from that B&G manual. [Click to enlarge any image]

Reader Comments & Q&AIt's possible that your heating system was at an overpressure because of a waterlogged expansion tank in the first place. On a typical residential hot water heating system the system pressure in the boiler should be around 12 PSI when the system is cold. Take a look at the heating system pressures articles in the article index. You shouldn't be needing to bleed air when you drain the expansion tank. If you have an air problem in your system it's a separate issue. Shut off supply valve to expansion tank. Opened drain valve and air valve on tank. Drained tank. Closed both valves....opened supply valve to tank. .Water pressure in system dropped so added water until gauge read 20 Lbs of pressure.... Bled air from system. Pressure dropped from releasing air pressure...added more water until pressure read 20 Lbs. Turned on heat. After heating awhile pressure read about 25-26 Lbs of pressure and water was dripping out of relief valve Relief valve is a 30LB relief valve. What have I done wrong. Should I have first bled air out of system then added water to bring pressure to 20Lbs then filled tank then bring pressure back up. I am concerned about the relief valve dripping Linda The water pressure tank (it's not an expansion tank) smooths the pressure or delivery of water into the building and prevents short-cycling or rapid on-off pump operation. If the water pressure tank becomes water-logged, that is if it loses its air charge, then the pump may cycle on and off very frequently, even every few seconds. That would show up as "constantly and rapidly changing water pressure". My water pressure keeps changing. Is this the expansion tank? Brian, sorry we were swamped. InspectAPedia.com has articles on AIRBOUND HEATING SYSTEM REPAIR, but as heating controls nay be missing I'd suggest a heating co. Service csll too. Let us know how you made out. and by "emergency relief valve " i mean the valve on the side of the boiler itself that is the same look as the one on my electric water heater i have a baseboard boiler system using natural gas. this summer copper thieves hit and i had to replace a number of lines. now when the system runs the downstairs heat zone will not warm up, i have bleed the lower section twice ( second time i just opened the pipe joint and let it run till clean water) now all of a sudden the system has no, ZERO, pressure while running and the whole upstairs zone will not bleed. i removed the whole bleeder valve on 5 sections and no water or air comes out. pump is pumping water, boiler is up to temp just no pressure. also the expansion tank is heavy and sounds full of water. i have had no leaks from the "emergency relief valve" and the system is hooked straight to city water with no pressure reducer. didnt know it was supposed to be there, copper thieves must have taken it. please help, too close to Christmas to have no heat!! ... Continue reading at EXPANSION TANK LEAK REPAIR FAQs or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX. Or see LEAKS into the BOILER CAUSE RELIEF VALVE LEAKS for other causes of leaks into a boiler that can cause TPR valve discharge Or see these Recommended ArticlesSuggested citation for this web pageEXPANSION TANK DIAGNOSIS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice. Or see this INDEX to RELATED ARTICLES: ARTICLE INDEX to HEATING BOILERSOr use the SEARCH BOX found below to Ask a Question or Search InspectApedia ... Ask a Question or Search InspectApediaTry the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly. Search the InspectApedia website Note: appearance of your Comment below may be delayed: if your comment contains an image, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay. Our Comment Box is provided by Countable Web Productions countable.ca Technical Reviewers & ReferencesClick to Show or Hide Citations & References |

zusammenhängende Posts

Werbung

NEUESTEN NACHRICHTEN

Toplisten

#1

#2

#3

Top 8 zeichnen lernen für kinder online 2022

1 Jahrs vor#4

Top 8 schluss machen trotz liebe text 2022

1 Jahrs vor#5

#6

Top 8 wie fallen calvin klein sneaker aus 2022

1 Jahrs vor#7

Top 5 mi band 3 schrittzähler einstellen 2022

1 Jahrs vor#8

#9

Top 9 sich gegenseitig gut tun englisch 2022

1 Jahrs vor#10

Werbung

Populer

Werbung

Urheberrechte © © 2024 wiewird Inc.